Material

NGP Multibarrier Paper is the combination of deforestation-free raw materials with a sustainable coating of unprecedented functionality. With this EU-compliant innovation, we are taking the issue of plastic waste prevention a quantum leap forward.

MULTIFUNCTIONAL.

SUSTAINABLE. RECYCLABLE.

NGP papers are made from tree-free or deforestation-free raw materials produced according to strict sustainability criteria. All NGP products are coated with a novel, water-based dispersion varnish that gives the paper barrier properties comparable to plastic. Free of toxic effects on the environment. At the same time, NGP products provide all the practical advantages crucial for the packaging industry in the future. A prime example is our premium paper made from sugar cane:

- resource-efficient production

- food-safe

- GMO-free

- free from bleaching agents and dyes

- excellent water, fat and water vapour barrier

- optional oxygen barrier

- cold and heat resistant

- sealable

- fully recyclable in the waste paper stream

- fully printable on non-coated side

NGP Produktflyer Downloads

ONE FOR ALL – THE POTENTIAL OF NGP MULTI-BARRIER PAPERS

Thanks to their universal material properties, multi-barrier papers from NextGenPaper can replace countless plastic packaging in the food and non-food sectors in the future.

Flow Packs

Flow Packs Sealed Trays & Cups

Sealed Trays & Cups Deep-Freeze Packaging

Deep-Freeze Packaging Dry Food Packaging

Dry Food Packaging Folding Boxes

Folding Boxes Take-Away & OTC Packaging

Take-Away & OTC Packaging Fruit & Vegetable Trays

Fruit & Vegetable Trays Candy Wraps

Candy Wraps Cardboard Tubes

Cardboard Tubes

EXAMPLES OF USE

- fruit and vegetables

- meat, fish and poultry

- frozen foods

- chilled foods

- ready meals

- dried foods

- savoury snacks

- sweets

- baked goods

- cheese and milk products

- tea and coffee

- other food products

- drinks

- pet food

- cosmetics and personal care products

- pharmaceutical and medical products

- tobacco

- to-go cups

The Perfect

Companion

The technical properties of

NGP multibarrier papers

The compatibility of NGP products is comprehensively certified. The same applies to the processing of our multi-barrier papers which can be produced on existing standard machines virtually without refitting effort. For the necessary minor adjustments, NGP the necessary know-how to ensure a smooth changeover from plastic packaging to sustainable NGP solutions.

Sustainability claims* for NextGenPaper include:

- PE-/PLA-free

- free of bisphenol A

- free of plasticisers

- free of PFAS (Per- und Polyfluroalkylderivaten)

- PVDC-free

- Halogen-free

- MOSH/MOAH-free

- temperature resistant between up to 140 °C

*compared to plastic

Certificates

- Direct food contact, Regulation (EC) 1935/2004, LFBG, (EU) No 10/2011, Swiss Ordinance SR 817.023.21

- Recycling PTS-RH 021:2012

- Oxygen ISO 15105-1

- Water vapour ISO 2528:2017-10

- Water ISO 535:2014-06

- Grease resistance according to ISO 16532-02:2007-09 & ISO 16532-01:2008-12

Standardised and

Compatible

The NextGenPaper production process

Our certified manufacturing process supports consistent sustainability management along the value chain. It enables the seamless tracing of raw material sources. And we have calibrated it for the greatest possible flexibility and productivity.

Paper

When selecting our paper suppliers, we urge them to be conscious of their carbon footprint, use environmentally friendly raw materials and comply with NextGenPaper values.

BARRIER-COATING

The patented, water-based and PE-/PLA-free NGP dispersion coating is our key technology. The worldwide demand for this INGEDE-certified coating from controlled production is met at the German site.

COATING PROCESS

NextGenPaper has patented its coating processes for various paper qualities. NGP products can therefore be manufactured to strictly controlled quality standards via licensees anywhere in the world.

All you need

NGP product range

The NGP product portfolio is essentially divided into three categories: NGP Resist (for non-food applications), NGP Barrier (for food packaging with water, water vapour and grease barrier) and NGP Barrier Oxy+ (with additional oxygen barrier*).

Our standard papers include recycled, kraft and sugarcane papers, as well as a translucent paper. What makes NextGenPaper truly special, however, is its versatility: nearly any type of paper can be enhanced with barrier properties.

*in the final stages of development

Multibarrier recycled paper

NGP Recycled Barrier– maximum sustainability

NGP Recycled Barrier Oxy+ – maximum sustainability, with oxygen barrier

Properties

- made from 100% recycled fibres for direct food contact

- unbleached paper quality

- available in grammages of 50 g/m² surface weight, other grammages available on request

Multibarrier Kraft Paper

NGP Kraftpapier Barrier – maximum sustainability

NGP Kraftpapier Barrier Oxy+ – maximum sustainability, with oxygen barrier

Properties

- high tensile strength

- high tear resistance

- high mechanical strength

- natural, brown or white colour

Multi-barrier paper, translucent

NGP Translucent Barrier – strong and translucent

NGP Translucent Barrier Oxy+ – strong and translucent, with an oxygen barrier

Properties

- white translucent paper

- smooth and tear-resistant surface

- excellent printing properties

- available in grammages from 45 - 90 g/m²

Multi-barrier sugarcane paper

NGP Sugarcane Barrier – maximum sustainability

NGP Sugarcane Barrier Oxy+ – maximum sustainability, with oxygen barrier

Properties

- made from the sugarcane waste from sugar production

- tree-free and deforestation-free

- unlimited availability

- natural brown colour

- available in grammages from 40 - 295 g/m² surface weight

The NGP All-Star

Tree-free Multi-Barrier Paper from Sugar Cane

Our multibarrier papers made from the sugar cane waste of sugar production are the beacon product from NextGenPaper. They are made from waste from the sugar cane industry called "bagasse". Qualitatively, they are in no way inferior to wood-containing paper - yet they are veritable sustainability champions:

- no additional areas under cultivation

- rapidly renewable raw material upcycling of a waste product

- lower raw material consumption compared to wood-containing paper bleech-free production, no optical brighteners, no colouring chemicals

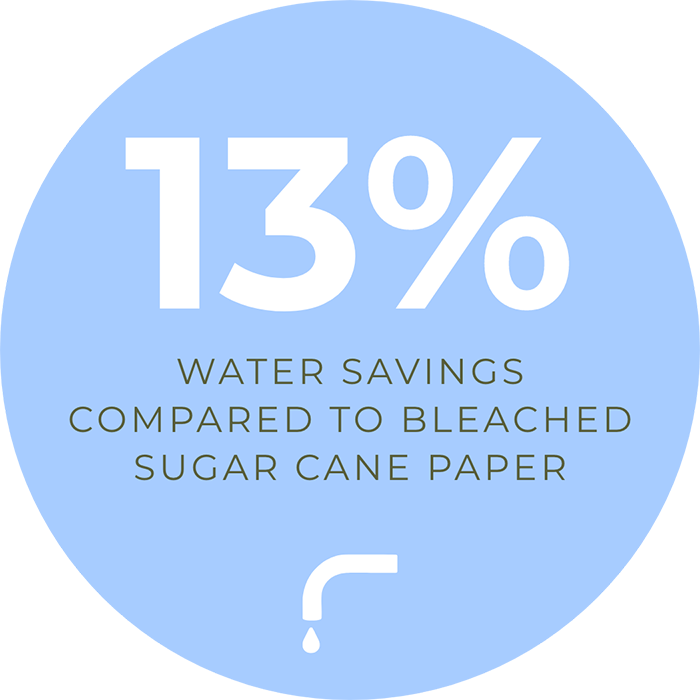

- natural coloured sugar cane paper saves 12.6% energy and 13.0% water (compared to bleached sugar cane paper)

- odourless pulping process that is harmless to health

Growth and Harvest Period

Today, 650 million tonnes of bagasse remain unused worldwide every year. At the same time, every fifth felled tree falls victim to the paper industry. By converting bagasse into paper, half of these trees could be saved.